30 Jaar Factory High Chrome Alloy Drijfmest Pomp

Productie van Sand pomp, baggerpomp, slib drijfmest pomp en reserveonderdelen.

NaiPu Belangrijkste producten

1. AH, AHF, Horizontaal Drijfmest Pomp

2. SP Verticale dompelpomp

3. ZJQ Submersible mestpomp

4. G horizontale zand grind pomp

5. ZJQ Submersible zandpomp

6. WS baggerpomp

7. Schuim AF Pump

8. OEM Gieten machines en onderdelen

NaiPu Main Pump Model

NaiPu kunnen vele soorten drijfmest pomp, niet beperkt tot de volgende modellen leveren

|

AH series

|

L(R) ,M

|

HH

|

SP(R)

|

G

|

AF Series

|

|

1.5/1B-AH(R)

|

20A-L

|

1.5/1 C-HH

|

40PV-SP(R)

|

6/4D-G

|

2QV-AF

|

|

2/1.5B-AH(R)

|

50B-L(R)

|

3/2D-HH

|

65QV-SP(R)

|

8/6E-G

|

3QV-AF

|

|

3/2C-AH(R)

|

75C-L

|

4/3E-HH

|

100RV-SP(R)

|

10/8F-G

|

6SV-AF

|

|

4/3C-AH(R)

|

100 D-L

|

4/3X-HH

|

150SV-SP(R)

|

10/8S-G

|

8SV-AF

|

|

6/4D-AH(R)

|

150E-L

|

6/4F-HH

|

200SV-SP

|

12/10G-G

|

|

|

6/4E-AH(R)

|

300S-L

|

6/4X-HH

|

250TV-SP

|

14/12G-G

|

|

|

8/6E-AH(R)

|

10/8 R-M

|

6S-H

|

|

14/12T-G

|

|

|

8/6R-AH(R)

|

10/8 E-M

|

8/6S-H

|

|

16/14 G-G

|

|

|

10/8F-AH(R)

|

|

8/6X-H

|

|

16/14TU-GH

|

|

|

10/8X-AH(R)

|

|

6S-HP

|

|

16/14H-GH

|

|

|

12/10ST-AH(R)

|

|

8/6S-HP

|

|

18/16G-G

|

|

|

14/12ST-AH(R)

|

|

8/6X-HP

|

|

18/16 TU-GH

|

|

|

16/14TU-AH(R)

|

|

|

|

|

|

|

20/18G(TU)-AH(R)

|

|

|

|

|

|

Horizontale Drijfmest Pomp Picture

Beschrijving

|

Index

|

Value

|

|

Products

Name

|

High Chrome Alloy Slurry Pump

|

|

Inlet Dia (mm)

|

1.5-20 inch

|

|

Outlet Dia (mm)

|

1.5-18inch

|

|

Flow (m3/h)

|

0-5400 m3/h

|

|

Head (m)

|

5-118 m

|

|

Max Power(kw)1

|

|

|

Material

|

High

Chrome A05

|

|

Drive

Type

|

CV / ZVz / CRz/ DCz

|

|

Drive Engine

|

Motor or Diesel

|

|

Seal

Type

|

Packing

Seal , Expeller Seal, Mechanical Seal

|

|

MQQ

|

1

set

|

|

Payment

Term

|

TT

, LC, or Negotiate

|

|

Original

|

ShiJiaZhuang

, Hebei China

|

|

Supply

Range

|

Slurry

Pump , Motor , Base Plate,Guard, v-belt , Pulley

|

|

Weight (KG)

|

|

|

Delivery

Term

|

By

Sea, By air , By TNT, DHL , By Train

|

Metal Horizontale Drijfmest Pomp Prestaties Parameter s

|

Type

|

Allowable

Mating Max. Power(Kw)

|

Clear

Water Performance

|

Impeller

|

|

Capacity/Q

m³/hr

|

Head/m

|

Speed/rpm

|

Max

Efficiency/%

|

NPSH/m

|

Nos

of Vane

|

Impeller

Diameter/mm

|

|

1.5X1-NP-AH

|

15

|

12.6--28.8

|

6--68

|

1200--3800

|

40

|

2--4

|

5

|

152

|

|

2X1.5-NP-AH

|

15

|

32.4--72

|

6--58

|

1200--3200

|

45

|

3.5--8

|

5

|

184

|

|

3X2-NP-AH

|

30

|

39.6--86.4

|

12--64

|

1300--2700

|

55

|

4--6

|

5

|

214

|

|

4X3-NP-AH

|

30

|

86.4--198

|

9--52

|

1000--2200

|

71

|

4--6

|

5

|

245

|

|

6X4-NP-AH

|

60

|

162--360

|

12--56

|

800--1550

|

65

|

5--8

|

5

|

365

|

|

8X6-NP-AH

|

300

|

360--828

|

10--61

|

500--1140

|

72

|

2--9

|

5

|

510

|

|

10X8-NP-AH

|

560

|

612--1368

|

11--61

|

400--850

|

71

|

4--10

|

5

|

686

|

|

12X10-NP-AH

|

560

|

936--1980

|

7--68

|

300--800

|

82

|

6

|

5

|

762

|

|

14X12-NP-AH

|

560

|

1260--2772

|

13--63

|

300--600

|

77

|

3--10

|

5

|

965

|

|

16X14-NP-AH

|

1200

|

1368--3060

|

11--63

|

250--550

|

79

|

4--10

|

5

|

1067

|

|

18X16-NP-AH

|

1200

|

2520--5400

|

13--57

|

200--400

|

85

|

5--10

|

5

|

1370

|

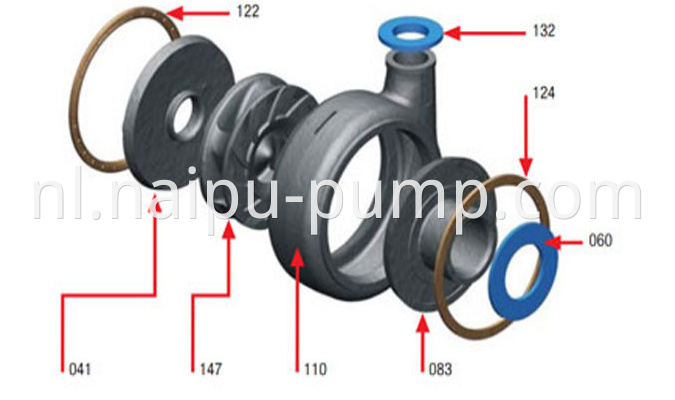

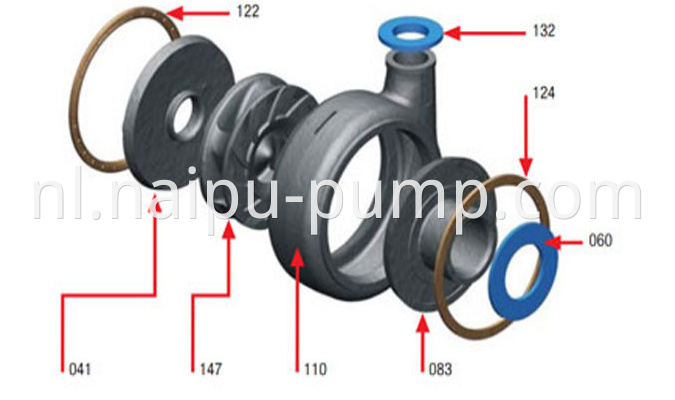

Horizontale constructietekening van centrifugaalpomp

Hoofdonderdeelnummer bij de tekening:

|

032:Frame Plate

060: Intake Joint

132:Discharge Joint

083:Throatbush

110:Volute Liner

147: Impeller

|

122: Stuffing Box Seal

036: Frame Plate Liner

013:Cover Plate

018:Cover Plate Liner

124: Volute Cover Seal

041: Frame Plate Liner Insert

|

Materialen van constructie

|

|

LINERS

|

IMPELLERS

|

CASING

|

BASE

|

EXPELLER

|

EXPELLER RING

|

SHAFT SLEEVE

|

SEALS

|

|

Standard

|

Chrome Alloy

Natural Rubber

|

Chrome Alloy

Natural Rubber

|

SG Iron

|

SG Iron

|

Chrome Alloy

or

SG Iron

|

Chrome Alloy

or

SG Iron

|

SG Iron

|

Rubber

and

Nitrile

|

|

Options

|

Ferralium

Hastelloy C

316 SS

W151

Polyurethane

Neoprene

Butyl

Viton

Nitrile

EPDM

Hypalon

|

Ferralium

Hastelloy C

316 SS

W151

Polyurethane

Neoprene

Butyl

Nitrile

Hypalon

|

SG Iron

Various grades

|

MS

Fabricated

Cast Iron

|

NI Resist

Ferralium

Hastelloy C

Polyurethane

316 SS

W151

|

NI Resist

Ferralium

Hastelloy C

316 SS

Rubber

W151

Polyurethane

Neoprene

Butyl

Nitrile

|

EN56C

Ferralium

Hastelloy C

Titanium

316 SS

304 SS

|

Ceramic

Stellite

Chrome Oxide

Nordel

Neoprene

Viton

|

Sollicitatie

De slurry pompen worden veel gebruikt in de mijnbouw, energie, metallurgie, steenkool, bang, bouwmaterialen en andere industriële lijnen concentraat residuen, slib en andere schuurmiddelen, hoge dichtheid slurry te pompen.

Field Applications:

Heavy Mining | Verwerking van mineralen | Coal Prep | Cycloon Feeds | Aggregate Processing | Fine Primaire Mill Grinding | Chemical Drijfmest service | tailings | Secundaire Malen | Industrial Processing | Pulp en papier | Food Processing | Kraakoperaties | Ash en bouwmachines | Pipeline Transport | High Velocity Hydraulic Transport | Food Processing | Explosieve slib in metaaluitsmelting | Rivier En Vijver Dredging | Heavy afvalverwijdering | Grotere Particle Of Low NPSHA toepassingen | Continu (Snurken) dompelpomp Bediening | Schurende Slurries | High Density Slurries || Grote Particle Slurries | Sump Drainage | Washdown | Floor Drainage | menging

Als u vragen heeft, neem dan contactus direct.

Contactpersoon: Kitty liu

Mail: kitty op naipump.com

Skype: kitty_naipump

WhatsApp: 86-13032609126