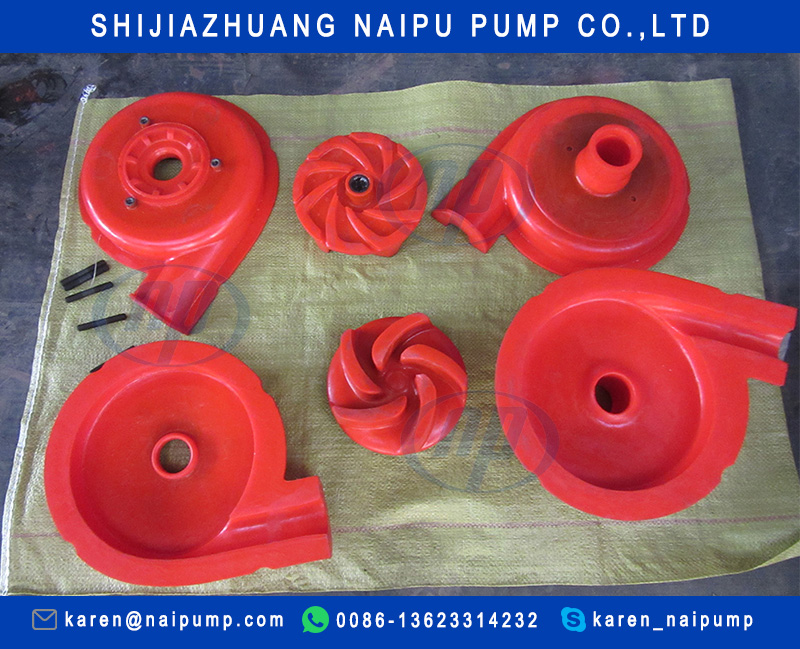

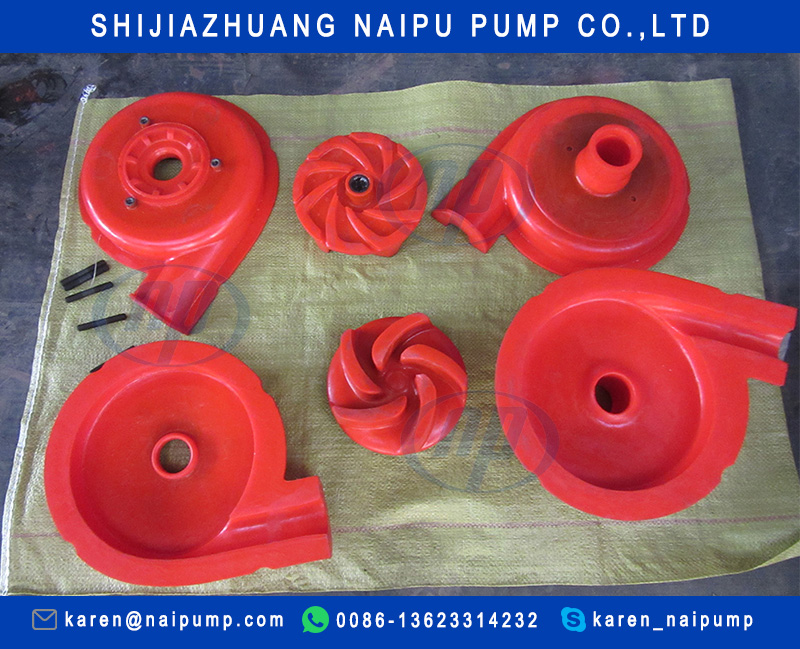

2 / 1.5B-AH polyurethaan pomponderdelen

Polyurethaan (PU ook genoemd) is an uniek materiaal ha is de elasticiteit van rubber in combinatie met de taaiheid en duurzaamheid van metaal. Het stelt de ingenieur in staat om rubber, plastic en metaal te vervangen met de ultieme slijtvastheid en fysieke eigenschappen. Polyurethaan kan het plantonderhoud verminderen.

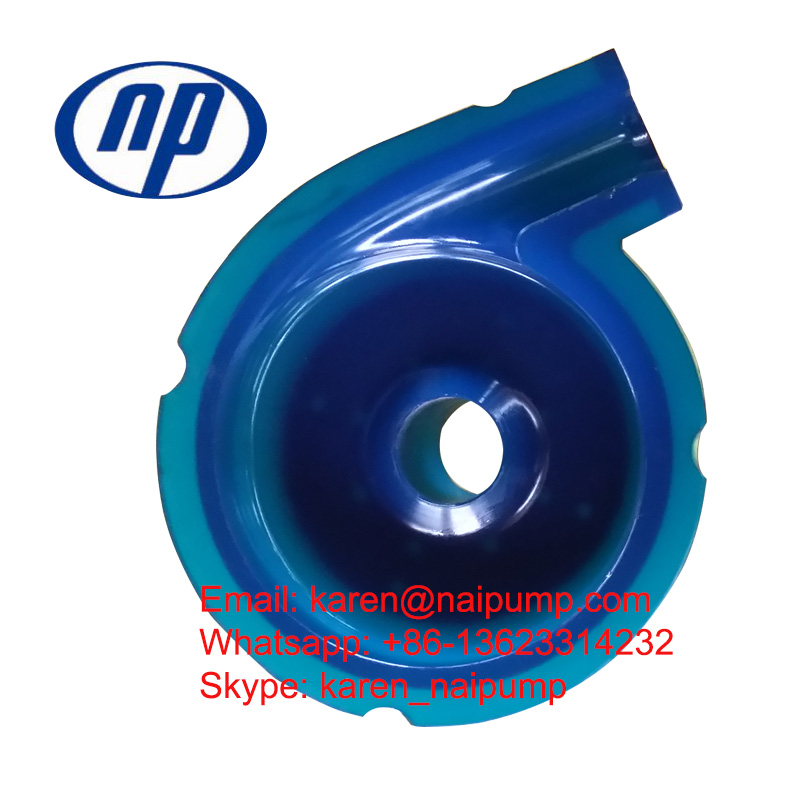

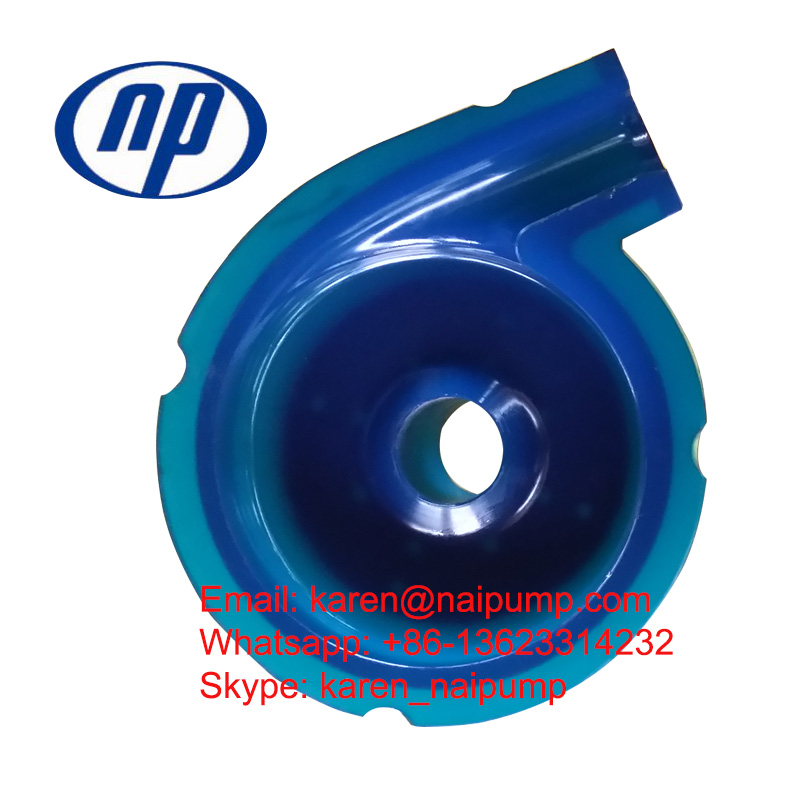

De pompwaaier van polyurethaan (PUR en PU) is gemaakt van polyurethaan, een polymeer dat is samengesteld uit een keten van organische eenheden die zijn verbonden door urethaanschakels. Deze waaier heeft betere prestaties dan een natuurlijke rubberen waaier voor het transport van slib.

Trouwens, we hebben ook polyurethaan afdekplaatvoering, frameplaatvoering, keelbus, frameplaatvoering-inzet enz.

Materials

|

NBR,Viton/FKM,Siicone/VMQ,EPDM,FFKM,HNBR,PU,CR,FVMQ,PTFE

|

Temperature

|

NBR(-40~120°C),CR(-40~120°C)

Viton(-20~200°C),Silicone (-70~220°C)

EPDM(-50~150°C),PU(-40~90°C)

|

Applied industry:

|

extensively used in chemical industry, petroleum industry, medical

technique, food industry, sewage-disposal industry, steel industry,

semi-conduct industry and so on.

|

Main advantage:

|

1) excellent anti-chemical character. It almost applies to all mediums.

|

|

2) temperature range is very wide.

|

|

3) anti oil function is very good.

|

|

4) long service life.

|

Operation conditions

|

Pressure:<50MPa

|

|

Temperature:-20°C ~ 220°C

|

|

|

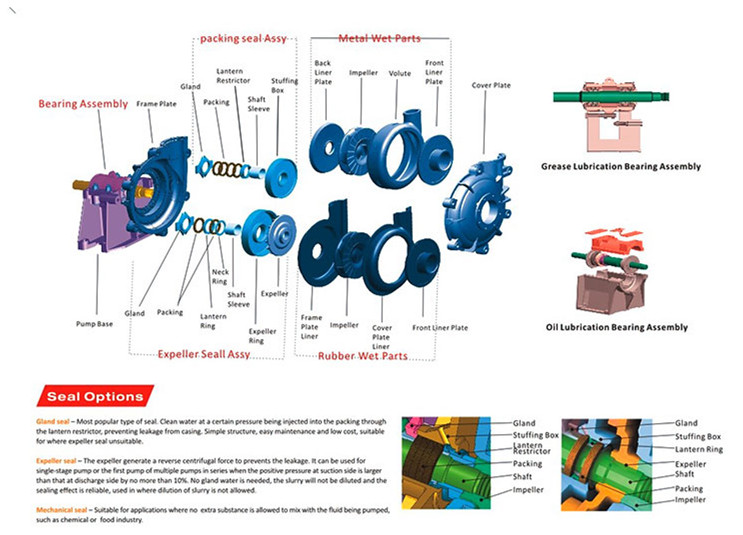

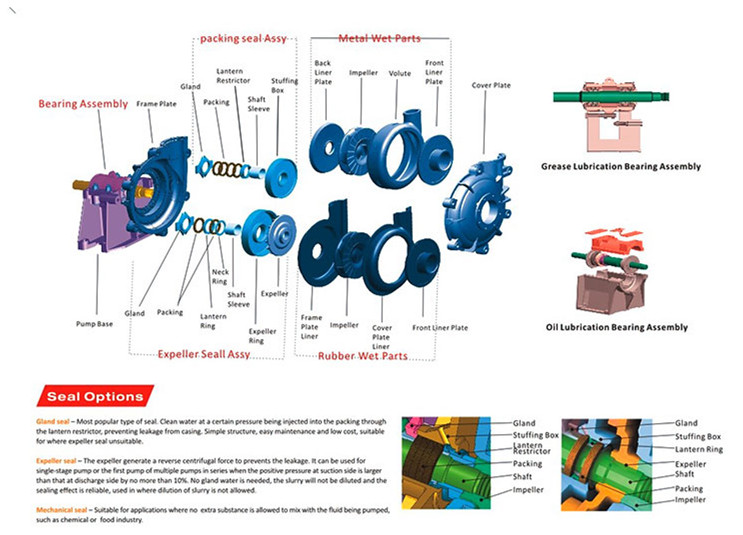

Bouwtekening:

Kenmerken

De slijtvastheid en scheurweerstand van urethanen zijn veel beter dan die van rubbers, terwijl ze een hoger draagvermogen hebben. Com p ared kunststoffen, urethanen superieure slagvastheid, terwijl uitstekende slijtage eigenschappen en elastisch geheugen. Daarnaast PU is ad v ance gewichtsreductie geluidshinder en slijtvastheid dan metaaldelen.

Urethanen zijn echter niet geschikt voor temperaturen boven 70ºC en voor geconcentreerde zuren en alkaliën, ketonen, esters, gechloreerde en nitrokoolwaterstoffen.

Productoverzicht:

Polyurethaan pomponderdelen / PU-onderdelen / polyurethaanonderdelen / OEM-drijfmestpomponderdelen / OEM-drijfmestpomp / OEM-waaier / OEM-pomponderdelen met hoog chroomlegering

Gerelateerde andere producten:

|

NAIPU Main Pump Material

|

|

Material

|

Description

|

Application

|

Pump Parts

|

|

A05

|

High Chrome Alloy Cr26

|

neutral ,resistant to alkali but not acid

|

Impeller,Liners

|

|

A49

|

Low Carbon High Chrome Alloy Cr26

|

usually in desulphurization condition

|

Impeller,Liners

|

|

A51(A33)

|

Wear Resistant and Abrasion resistant alloy

|

usually in phosphuric acid,desulphurization and Sulfuric acid working conditions

|

Impeller,Liners

|

|

C21

|

Martensitic Stainless Steel

|

|

Shaft Sleeve,Locating Sleeve

|

|

C23

|

Austensitic Stainless Steel

|

|

Lantern Ring,Lantern Restrictor,Packing Gasket

|

|

D21

|

Ductile Iron

|

|

Cover Plate,Frame Plate,Bearing Housing ,Frame

|

|

D81

|

Galvanized Ductile Iron

|

|

Packing Gland

|

|

E02

|

20# Steel

|

|

|

|

E62

|

20# Galvanised Steel

|

|

|

|

E05

|

45# Steel

|

|

Shaft ,Shaft Key

|

|

E65

|

45# Steel

|

|

|

|

G01

|

HT200

|

|

|

|

G61

|

Gray Iron

|

Base ,Bearing Housing,Frame Plate/Cover Plate,Grease Retainer,Lower Strainer

|

Labyrinth Ring,End Cover

|

|

J04

|

C21 Alumina Plating

|

|

Usually white color ,Shaft Sleeve

|

|

J05

|

C21 Chromic Oxide Plating

|

|

Usually black color,Shaft sleeve

|

|

Q21

|

Aramid fiber ,yellow

|

|

Packing

|

|

R08

|

Natural Rubber

|

|

impeler

|

|

R26

|

|

|

impeller

|

|

R33

|

Natural Rubber

|

|

cyclone liners,pump liners,impeller etc.

|

|

R38

|

Natural Rubber

|

|

impeller

|

|

R55

|

Natural Rubber

|

|

impellers,liners

|

|

S01

|

EPDM

|

Acid Resistant but not wear resisting,high temperature

|

Discharge Gasket,Intake Gasket,Volute Liner Seal ,also for wet end parts

|

|

S10

|

Nitrile Butadiene Rubber

|

|

O Rings

|

|

S12

|

|

|

impeller, liners

|

|

S31

|

Hypalon

|

|

|

|

S21

|

Butyl Rubber

|

high temperature resistant and antioxidant

|

impellers,liners

|

|

S42

|

Neoprene Rubber

|

High Temperature resistant ,weather resistance,ozone resistance,Grease Resistance

|

impeller,Liners

|

|

U01

|

Polyurethane

|

Tension Resistance,High Tensile strength

|

impeller,Liners

|

|

S44

|

Neoprene Rubber

|

|

|

|

S50

|

Fluororubber

|

High Temperature and acid resistant,

|

Gasket ,wet end parts

|

|

Y08

|

Ceramic

|

|

|

|

J31

|

|

|

Shaft Sleeve

|

|

J26

|

Ceramic coated stainless steel

|

J26 consists of Y03 Ceramic Coating deposited onto a C26 substrate using a special spray technique.The coating is very hard and offers excellent abrasive wear resistance.The spray technique gives a coating with minimal porosity and excellent interlayer bond strength.J26 is expansion and will not spall.

|

|

|

Basic Part No.

|

Material Code

|

Part Name

|

|

001

|

E62

|

Adjusting Screw

|

|

003

|

G01

|

Base

|

|

005

|

|

Bearing Assembly

|

|

011

|

E62

|

Clamp Washer

|

|

013

|

D20

|

Cover Plate

|

|

015

|

E62

|

Cover Plate Bolt

|

|

017

|

R26A

|

Cover Plate Liner

|

|

018

|

R26A

|

Cover Plate Liner (Half)

|

|

024

|

E62

|

End Cover

|

|

028

|

G01

|

Expeller

|

|

029

|

G01

|

Expeller Ring

|

|

029R

|

R08A

|

Expeller Ring (Rubber)

|

|

032

|

D20

|

Frame Plate

|

|

034

|

E62

|

Frame Plate Bolt

|

|

036

|

R26A

|

Frame Plate Liner

|

|

039

|

E63

|

Frame Plate Stud

|

|

041

|

A05A,R26A

|

Frame Plate Liner Insert

|

|

043

|

R26A

|

Frame Plate Liner (Half)

|

|

044

|

K24

|

Gland Assembly

|

|

060

|

R08A

|

Intake Joint

|

|

062

|

D70

|

Labyrinth

|

|

063

|

K31

|

Lantern Ring

|

|

064

|

S18

|

Impeller O-Ring

|

|

067

|

E62

|

Neck Ring

|

|

070

|

E05

|

Shaft Key

|

|

073

|

E05

|

Shaft

|

|

075

|

D20

|

Shaft Sleeve

|

|

076

|

D20

|

Shaft Sleeve (Long)

|

|

078

|

G01

|

Stuffing Box

|

|

081

|

E02

|

Keeper Plate

|

|

083

|

A05A,R26A

|

Throat Bush

|

|

085

|

E02

|

Cotter

|

|

090

|

S10

|

Lip Seal

|

|

109

|

S18

|

Shaft O-Ring

|

|

110

|

A05A

|

Volute Liner

|

|

111

|

Q05

|

Packing

|

|

117

|

E62

|

Shaft Spacer

|

|

118

|

K31

|

Lantern Restrictor

|

|

118-1

|

K24

|

Lantern Restrictor(Low Flow)

|

|

122

|

R11A

|

Expeller Ring/Stuffing Box Seal

|

|

124

|

R08A

|

Volute Liner Seal

|

|

125

|

R08A

|

Volute Frame Seal

|

|

132

|

R08A

|

Discharge Joint Ring

|

|

138

|

E62

|

Grease Cup Adaptor

|

|

179

|

C23

|

Shaft Sleeve Spacer

|

|

210

|

S46

|

Shaft O-Ring

|

|

217

|

S18

|

Impeller O-Ring

|

|

239

|

C23

|

Impeller Release Collar

|

|

241

|

K24

|

Lip Seal Gland

|

|

302

|

E02

|

Lifting Tube

|

|

303

|

E02

|

Locating Nut

|

|

304

|

E02

|

Volute Lifting Beam

|

|

306

|

E02

|

Shaft Wrench

|

|

310

|

E02

|

Stuffing Box / Expeller Ring

|

|

425

|

R08A

|

Dyna Seal

|

|

430

|

U14

|

Nut Covers

|

|

005

|

|

Bearing Assembly

|

|

019

|

E02

|

Mounting Plate

|

|

041

|

A05A

|

Back Liner

|

|

064

|

S18

|

Impeller O-Ring

|

|

070

|

E05

|

Shaft Key

|

|

092

|

A05A

|

Casing

|

|

102

|

E02

|

Column

|

|

116-1

|

R10A

|

Strainer - Upper (Rubber)

|

|

116-2

|

G01

|

Strainer-Upper (Cast Iron)

|

|

116-3

|

U02A

|

Strainer-Upper(Urethane)

|

|

116-4

|

C23

|

Strainer-Upper(SS Mesh)

|

|

116L

|

U01A

|

Strainer-Lower

|

|

125

|

R08A

|

Back Liner Seal

|

|

154

|

E02

|

Discharge Pipe

|

|

204

|

R00

|

Discharge Pipe Gasket

|

|

231

|

E02

|

Suction Pipe

|

|

290

|

E02

|

Spacer

|

|

293

|

E02

|

Discharge Pipe Support

|

|

306

|

E02

|

Shaft Wrench

|

|

430

|

U04A

|

Nut Covers

|

|

005

|

|

Bearing Assembly

|

|

019

|

|

Mounting Plate

|

|

041

|

|

Back Liner

|

|

064

|

|

Impeller O Ring

|

|

070

|

|

Shaft Key

|

|

092

|

|

Casing

|

|

102

|

|

Column

|

|

116

|

|

Strainer-Upper

|

|

116L

|

|

Strainer-Lower

|

|

153

|

|

Column Clamp

|

|

154

|

|

Discharge Pipe

|

|

290

|

|

Spacer

|

|

291

|

|

Socket Head Protectors

|

|

293

|

|

Discharge Pipe Support

|

|

306

|

|

Shaft Wrench

|

|

421

|

|

U-Bolt

|

Material Code

|

Applications

|

Remarks

|

G01

|

Casing,Frame,Bearing Housing,Stuffing Box,Stuffing Gland

|

Grey Iron

|

D21

|

Casing,Frame,Bearing Housing

|

Spheroidal Graphite Cast Iron

|

A05/A33

|

Impeller,Volute,Expeller,Throat Bush,FPL,Expeller Ring

|

High Chrome Alloy

|

A49

|

Impeller,Volute,Throat bush,FPL

|

|

R26/R33/R55

|

Impeller,Volute,Throat bush,FPL

|

Rubber

|

OEM Material

|

Special material for pumps and pump parts are available according to clients chemical component request.

|

|

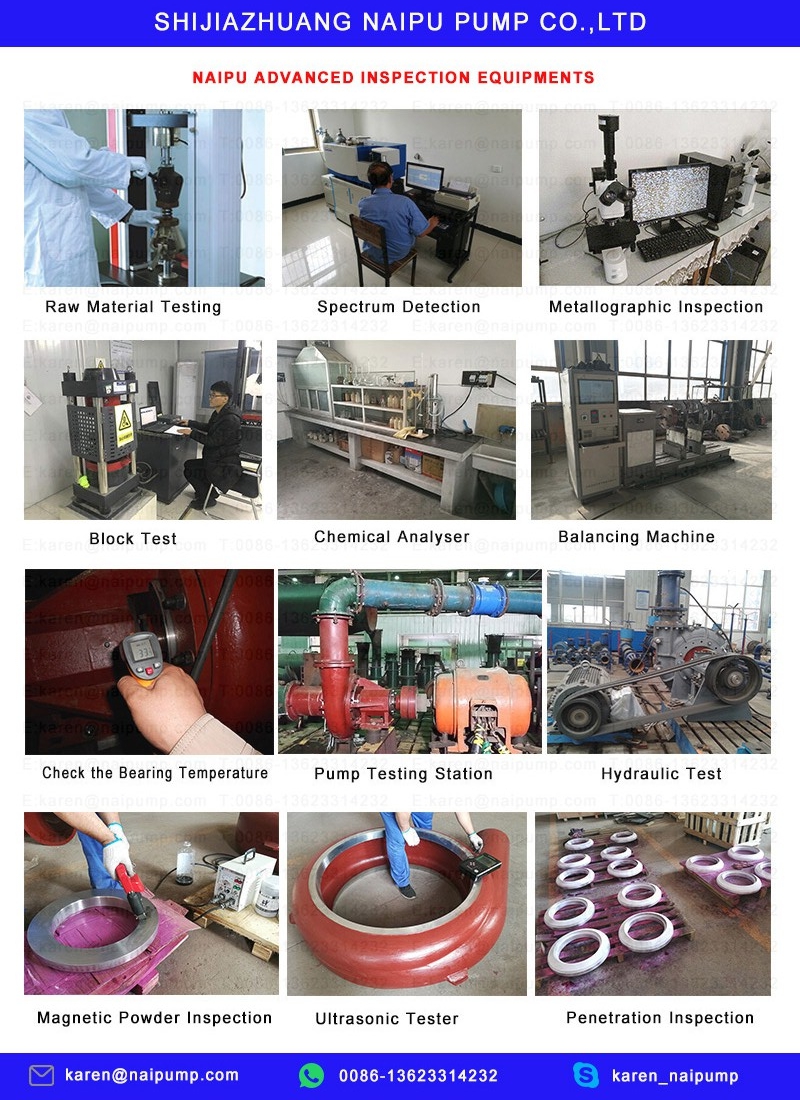

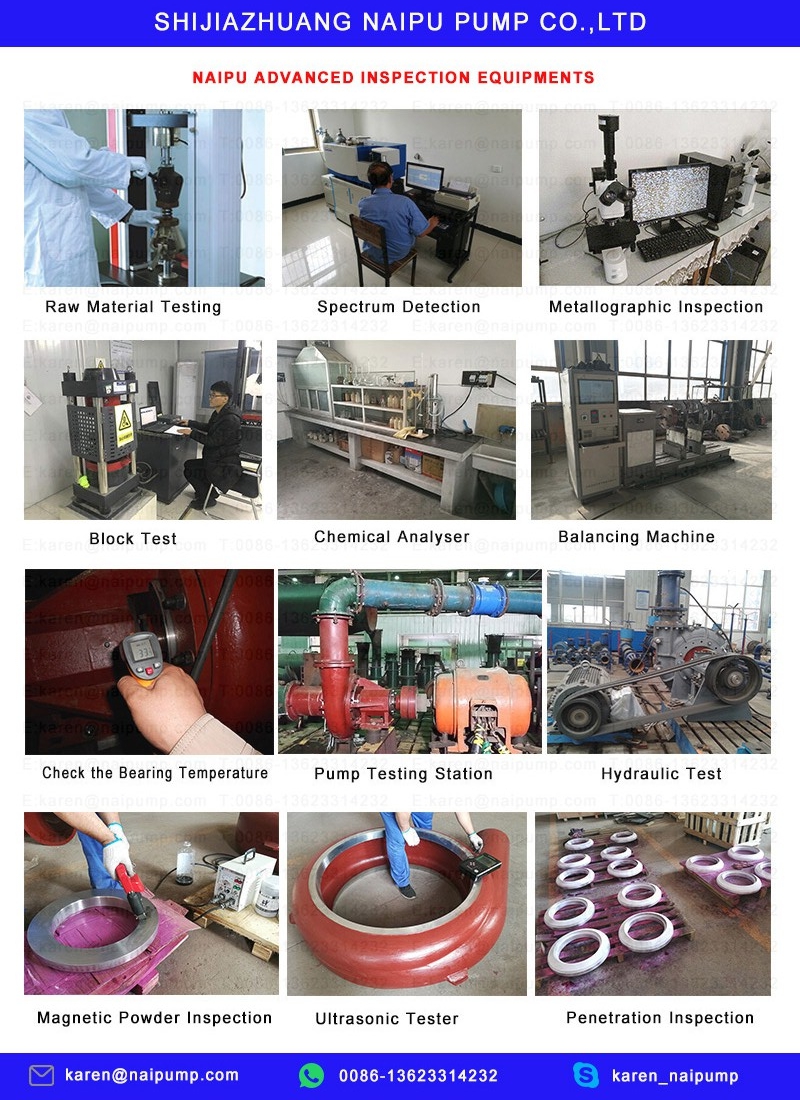

Kwaliteitscontrolesysteem:

We hebben verschillende controlepunten langs de hele productielijn ingesteld, die door het controleren van grondstoffen, laadmateriaal, oppervlakte- en warmtebehandeling, materiaalanalyse, reservetests en pomptests enz.

We hebben een strikt QA- en QC-systeem opgezet, we kunnen kwaliteitscontrolegegevens verstrekken, zoals "Spectrumdetectie", "Metallografische microscoopinspectie", "Bloktest" Ultrasone foutdetectie", "Penetratietesten" enz. En gerelateerde testrapporten aan onze klanten indien nodig , zoals "Materiaal testrapport" "Dimensionale testrapport" "Rotorbalanceringstestrapport" "NDT-testrapport" "Hardheidsinspectierapport" enz.

Contact details:

Shijiazhuang Naipu Pump Co., Ltd

Toevoegen: No.368 Xinshi North Road, Shijiazhuang Hi-Tech Industry Development Zone, Hebei, China 050091.

Skype:karen_naipump

Contactpersoon: Karen Tan

Als u vragen heeft, neem dan gerust contact met ons op.